Equipment catalogue

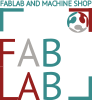

device for measuring the geometric characteristics of the object. Measurement takes place by using a sensor that is attached to a movable axis. Measurement takes place by the constant contact method (probe). The machine allows to measure all possible types of deviations of geometric surfaces (parallelism, alignment, taper, deviation of linear dimensions, etc.)

- Working place: 500 x 700 x 400 mm;

- Max weight of a workpeice :180 kg.

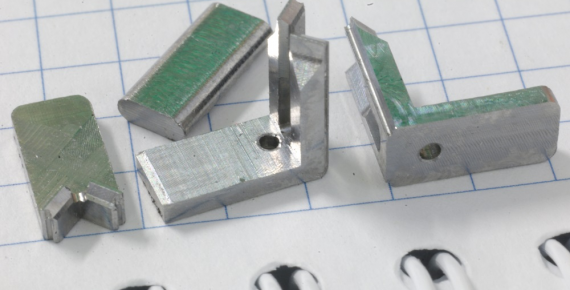

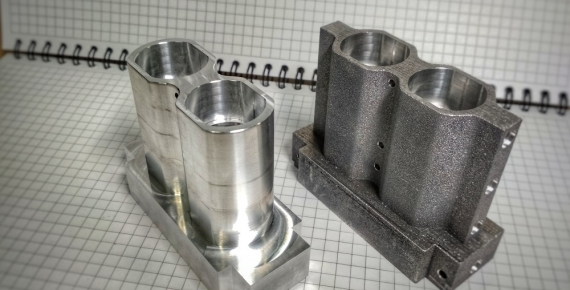

The machine allows you to cut an electrically conductive materials, from aluminum and copper to graphite and polycrystalline diamond. The EDM technology allows you to achieve the extreme precision in the production with a quite high cutting speed. This processing technology allows you to obtain parts with a small roughness (up to 0.2 Ra for materials of high hardness).. Hower the capabilities of the machine are not limited just to the manufacture of dies and molds. The machine coul be an alternative to milling, turning, grinding or broaching equipment. 4-axial execution of machine mechanics (independent movement of the upper and lower spinnerers) allows to manufacture inclined surfaces and cones, as well as difficult-shaped products.

- Max workpiece size 810x700x215 mm;

- Max workpeice weight 500 kg;

- Workplace size 640x540 mm;

- Axis motion (X/Y/Z) 400x300x220 mm;

- Wire slope angle/workpiece hight 15°/200 mm, 30°/87 mm;

- Min cut thickness - 0.35mm (optional 0.2mm).

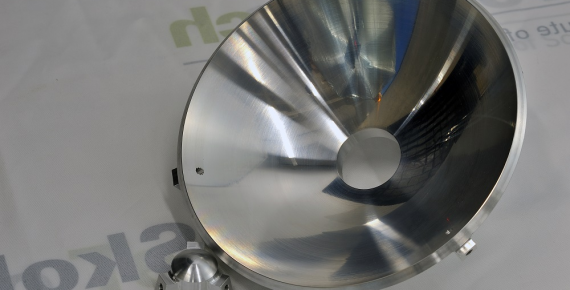

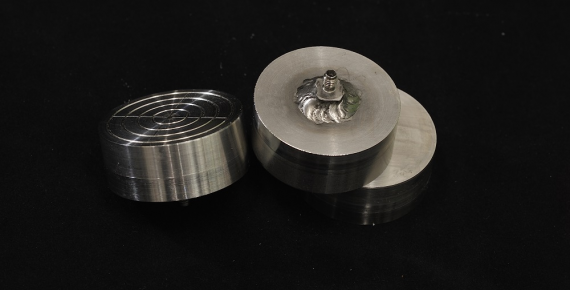

Haas’s triple-axis turning center allows you to perform a wide range of tasks: cutting external and internal threads; processing of various surfaces of solids of revolution (turning, undercutting of the flat end, segment and grooving). The center is equipped with a multi-position tool changer (up to 36 positions) and a continuous supply of lubricating coolant to the treatment area, which allows an efficient material removal and high machining accuracy.

Haas’s dual-axis turning center allows you to perform a wide range of tasks: cutting external and internal threads; processing of various surfaces of solids of revolution (turning, undercutting of the flat end, segment and grooving). The center is equipped with a multi-position tool changer (up to 12 positions) and a continuous supply of lubricating coolant to the treatment area, which allows an efficient material removal and high machining accuracy.

- Max diameter of a workpiece - 180mm;

- Max poreccesin length 270 mm;

- Max Power/spindle torque 11.2 Kv/ 102 Nm;

- Weight of the center 3.5т.

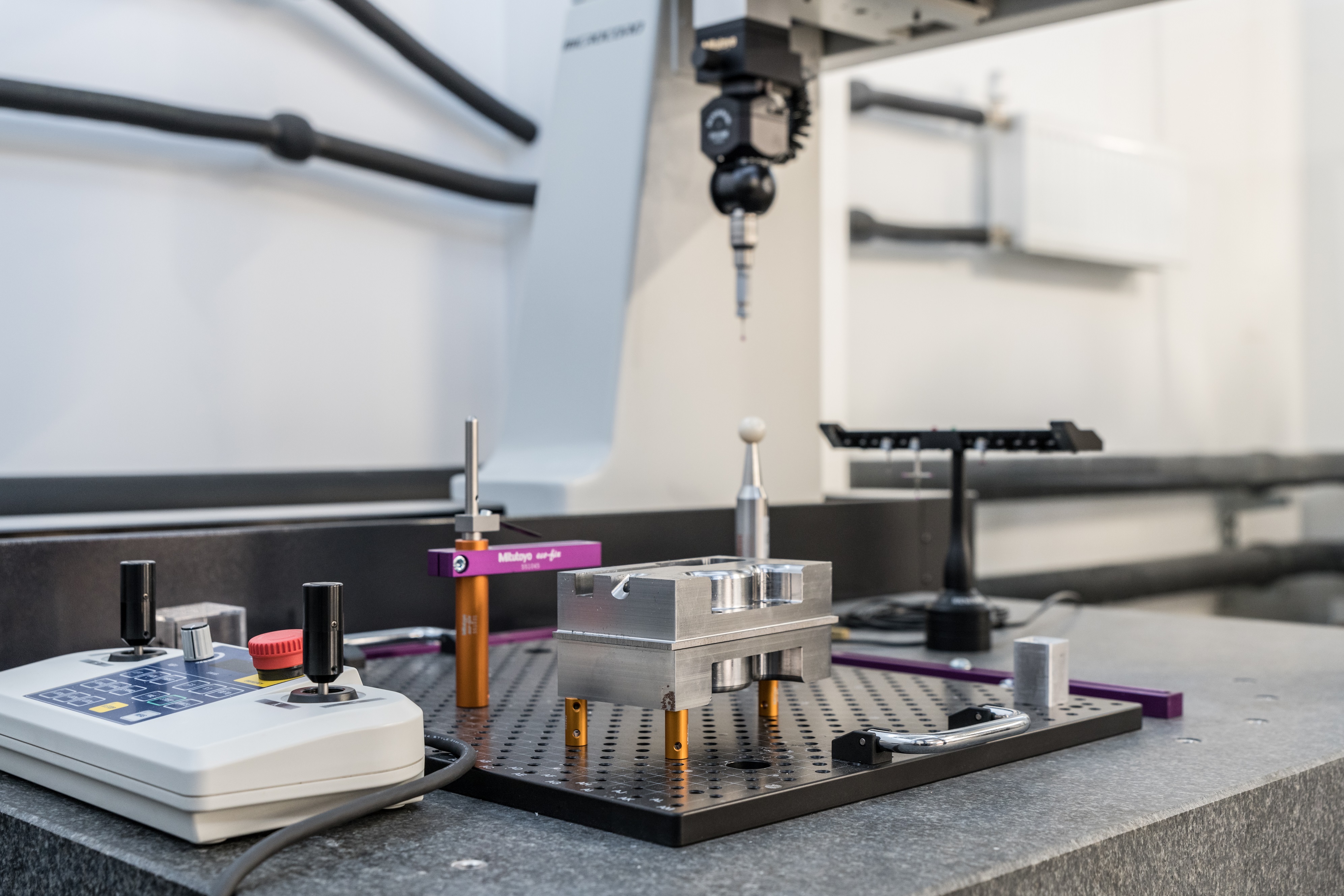

The 4-axis machining center is designed for quick and high-precision machining by using various tools and operations. The station can operate both in automatic mode and in semiautomatic mode; in these modes, production centers perform the same operations as drilling and milling machine tools. They can drill, reamer, mill, open a hole and cut external and internal threads. The main components that distinguish the machining center from CNC machines are a multi-position tool changer; that is capable of using a large number of tools (up to 17 tools fit into the holder) and a special new generation program control. The unique positioning system of the tool relative to the workpiece allows to acheive a high machining accuracy and to significantly reduce the performance time of all operations Thanks to the preparation of control programs in CAD systems, it is possible to manufacture complex-shaped products and multilate machining of parts in one set.

- Working place 508×406×394 mm;

- Table size withT-shaped groove — 660×381 mm;

- Max weight of a workpeice - 113kg;

- Power of the vector drive — 15 h.p.;

- Torque fot miling and drilling — 62Nm;

- Weight of the machine 2.7т.

The station is designed to process various workpeices made out of metal or plastic. This machine allows you to work with external and internal surfaces. Universal milling machine could be used for milling and drilling. The design of this model includes the following design features: The vertical console could move in the accelerated mode;

The table can move fully automatically in one of two directions;

There are special computing systems that allow measurement at once along all three axes.

- Workplace size - 1370х250mm;

- Axial movement XYZ - 800/440/200mm;

- Spindle RPM 60-4200 trn/min;

- Machine weight 1200kg.

Designed for processing rotation bodies by removing chips from them during turning. The machine can perform various types of turning: turning cylindrical, conical, shaped surfaces, cutting edges, cutting, boring, as well as drilling and reaming, threaded and rolling grooves, grinding, etc. The model is equipped with a foot brake, working light, water cooling system, indication strips to control the position of the cutting tool relative to the workpiece. This machine is widely used in experimental and small-scale production.

- Max workpeice diameter - 250 mm;

- Max workpeice lenght 1200 mm;

- Axle RPM 25-1800 trn/min;

- Max spindle power 5.5 Kv;

- Machine weight: 3т.

The machine is made for drilling, countersinking, counterbore and reame holes in the products of a wide group of materials. Due to eight spindle rotational speeds, it is possible to select the optimum mode of tool operation depending on the type of material.

- Max drilling diameter 30 mm;

- Spindle RPM 75- 3150trn/min;

- Quill stroke150 mm;

- length between the spindle and the table 910 mm;

- Workplace size 405x505 mm;

- T-shaped grooves, 2 по 16 mm Power 1,1 Kv;

- Machine size 800x600x1840mm;

- Weight 198 kg.

Designed for cutting products from steel, as well as non-ferrous metal alloys of various profiles.

- Workplace at 90° .Ø 200мм, 355x200мм;

- Workplace at 45°. . Ø165мм, 152x165 мм4

- Pulley diameter 305 мм;

- Workplace hight 640 мм;

- Belt size.20х0,9х2463 мм;

- Belt movement speed.34/ 50/ 65 m/min.

Using the machine, you can quickly and efficiently carry out straight, curvilinear, manual, as well as external and internal cutting of various parts and blanks made of aluminum, mild steel, brass, copper, ceramic tile, wood and other materials.

- Processing materials metal, wood, plastic, pressed paper, fibrous materials Cut angle, deg. -45...+15;

- Max workpeice diameter 90°, mm 400;

- Max size of a rectangular workpeice 90°/45°, mm 400х285;

- Beltsaw size, mm 3- 16х3390-3467;

- Cooling system Plate width, mm 3-16.

universal sources of welding current for industrial use: mechanized welding in the environment of protective gases and their mixtures (MIG / MAG), flux-cored wire welding (FCAW) and manual arc welding (MMA).

- Type semiautomaticinvertot Idling voltage, V65;

- Welding current, A 20–350;

- Switching frequency 60%;

- Welding type MIG, MMA;

- Max. electrode diameter five Wire diameter, mm 0.8 - 1.6;

- Wire feed speed, m / min 1.5-16.

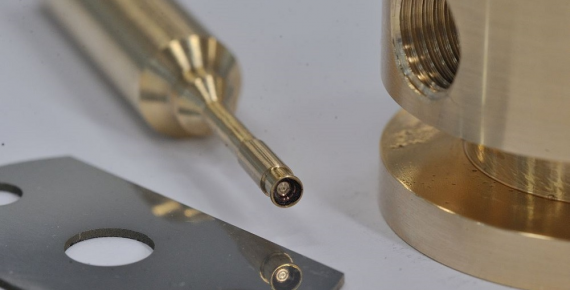

Machine is designed for machining rotation bodies of non-ferrous metals and plastics by removing chips from them during turning. The machine can perform various types of turning: turning cylindrical, conical, shaped surfaces, cutting edges, cutting, boring, as well as drilling and reaming holes, threading and knurling grooves, grinding, etc.

- The diameter of the hole in the spindle: 21 mm;

- Maximum length of the workpiece: 550 mm;

- Maximum movement of quill: 68 mm;

- Maximum diameter of processing over a bed: 250 mm;

- Maximum working diameter over a caliper: 150 mm;

- Range of feed: 0.1-0.25 mm / rev;

- Spindle rotation speed limits: 125-2000 rpm;

- Inch thread cutting steps: 8- 56 turns / "";

- Steps of cut metric threads: 0.1-2.5 mm.

The machine is designed for processing various parts and blanks, if they are made of non-ferrous metals, plastic or wood. Processing is carried out by a special cutting edge located on the axial tool. This machine allows you to work with external and internal surfaces, to make grooves, ledges, and so on.

- Rotation of the milling head ± 90 °;

- Movement along the Z axis, mm 280;

- Size of the table, mm 700 x 180;

- Movement along the X axis, mm 480;

- Movement along the Y axis, mm 175;

- Maximum load on the table, kg 55.

The three-axis low power CNC milling machine allows milling and mechanical engraving of the material. It is capable to mill materials with a density up to 2000 kg / m3. Using the methods of engraving it is possible to manufacture the base element of printed circuit boards by removing copper from the surface of foiled fiberglass. Thanks to the closed chamber it can be operated in relatively clean rooms.

- Max. Working area mm

- 203.2 x 152.4 x 60.5

- Max. workpiece weight 2 kg

- Spindle speeds up to 7000 rpm

The three-axis CNC milling machine allows milling and mechanical engraving of the

material. It is capable to mill materials with a density up to 3000 kg / m3. Using the methods of engraving it is possible to manufacture the base element of printed circuit boards by removing copper from the surface of foiled fiberglass. Additionally, it is possible to install the kinematics of the 4th axis, which expands the capabilities of the machine tool and allows production of products of complex shapes

- "Materials to be processed plastics, wood, non-ferrous metals

- Movement along the X / Y / Z axis, mm X x Y x Z: 500 x 400 x 155 mm

- Distance from spindle nose to table max. 254 mm.

- The size of the table length x width: 550 x 420 mm

- The maximum weight of the workpiece is 20 kg.

- XY motors servos, 60W 0.001 mm mechanical resolution

- Positioning accuracy ± 0.1 mm / 300 mm, no load

A three-axis CNC milling machine with a high power spindle and a large working field allows to machine materials with a density of up to 4000 kg / m3. Due to the size of the working field, it is possible to manufacture large functional products.

- Max. working area 2.67 m x 1.24 m x 0.2 m;

- Positional repeatability: ± 0.05 mm.

Planer with mechanical feed serves in smallscale production. Two high-speed steel knives provide the optimum result of the surface treatment of the timber. For fine adjustment of chip thickness, as well as for fast and accurate planing, there is a well-readable scale. The perfectly smooth surface of the table facilitates the process of feeding the workpiece due to good sliding.

- Max processing width, mm 304;

- Number of knives, pcs 2;

- Planing debth, mm 3;

- Max planing depth (surface gage), mm 3;

- Frequency of rotation of a planing shaft, rpm 8500;

- Min workpiece thickness (gauge), mm 3;

- Max workpiece thickness (gauge), mm 155;

- The speed of movement of the part (gauge), m / min 8.5.

Machine is used for transverse and longitudinal cutting of slab materials, for milling overhangs of edging materials, and lining edges of sheet blanks and shields

- Workspace size: 900x550 mm;

- The maximum width of the workpiece when sawing with a parallel emphasis on the right: 1300 mm;

- Sizes of a mobile table (DhSh): 3200х360 mm;

- Maximum width to limit stop of the end stop of the movable table: 1800 mm;

- Moving table (carriage) stroke: 3200 mm;

- The maximum length of the cut on the movable table: 3200 mm.

Using the machine, you can quickly and efficiently carry out straight, curvilinear, manual, as well as external and internal cutting of various parts and blanks made of aluminum, mild steel, brass, copper, ceramic tile, wood and other materials.

- Processing materials metal, wood, plastic, pressed paper, fibrous materials

- Cut angle, deg. -45...+15

- Max workpeice diameter 90°, mm 400

- Max size of a rectangular workpeice 90°/45°, mm 400х285

- Beltsaw size, mm 3- 16х3390-3467

- Cooling system

- Plate width, mm 3-16

Machine for drilling, countersinking and reamimg holes in products that are non-ferrous metals, plastics or wood

- Max drill diameter, mm 40;

- Spindle speed, rpm 200- 850 / 600-2500;

- Size of the base, mm 330x350.

The machine is used for sharpening, adjusting the geometry and deburring steel products of varying degrees of hardening.

- Bore diameter 15 mm;

- The diameter of the grinding wheel 205 mm;

- Circle thickness 19 mm;

- Frequency of rotation is 2850 rpm.

This machine is used for flat grinding the surfaces of products. Adjustable supports allow you to select the relative angles of the surfaces of the part

- Power (W) 1000;

- Rotational speed grinding circle, rev / min 1400;

- Diameter of the disk, mm 230;

- Belt speed, m / min 600;

- Tape width, mm 150;

- The length of the tape, mm 1220;

- The size of the desktop, 300x250 mm;

- Tape angle, hail. 0-90;

- Table tilt angle (tape), hail 0-45;

- Table tilt angle (disk), hail 0-4.

It is used to prepare the surfaces for the future coating or to acheive low roughness

- Power 300 W;

- Revolutions (rpm) 12000;

- The amplitude of 2.8 mm;

- Circle (mm) 125;

- Fastening sanding sheets Velcro.

This machine is used for cutting and linear cutting of wood, MDF, plywood and various plastics with thickness up to 50mm

- Power 1200 W;

- Max. turns 5300 rpm;

- Outer diameter 160 mm;

- Bore diameter 20 mm;

- Cutting depth (max) 55 mm;

- Max. depth of cut at an angle of 90 ° 55 mm;

- Max. depth of cut at an angle of 45 ° 38 mm.

Used for, linear and shape cutting of wood products, MDF, plywood and various plastics with a thickness of up to 20 mm

- Power 530 W;

- The frequency of the rod movement (strokes / min) 500-3100;

- Max. stroke frequency 3100 strokes / min;

- Number of positions of the pendulum stroke 4;

- The course of a file is 26 mm;

- Max. material thickness (wood) 75 mm;

- Max. material thickness (metal) 5 mm.

Hand power tool with a variety replaceable nozzles. Principle of operation it consists in oscillatory motion nozzles. Nozzles are cutting and sander. The geometry of the nozzles

will allow to process hard-to-reach places and surfaces.

- Power, 320 W;

- Ois connection type;

- Oscillation frequency,number/min 6000-20000;

- Electra. adjustment turnovers;

- Cable length, m 2.5;

- Angle of oscillation, deg.3.2.

Belt rasp is intended for grinding, satinishing and cleaning products in hard-to-reach places.

- Power 550 W;

- Type of grinding tape machines;

- Maximum belt speed 1000 m / min;

- Tape size (mm) 30x533;

- Tape width 30 mm;

- Tape length 533 mm.

Mechanical scissors are designed to work with sheet metal, corrugated and trapezoidal corrugated sheet. The cutting head rotates 360 degrees and is installed in four positions, in increments of 90 degrees.

- Power 550 W;

- The number of moves 2200 stroke / min;

- Max. material thickness (metal) 2.5 mm;

- Min 45 mm cutting radius.

The power mechanism providing 30 tons pressure between working surfaces. It can be used for product development as well as to participate in assembly and demountable operations of parts with tightness

- Force 30 tons Stroke L mm 50;

- Working range F mm 151- 1031;

- Nominal air pressure atm 8 - 9;

- Horizontal cylinder stroke M mm 200.

The machine is designed for preparation surfaces of products before applying various coatings, removal of rust, scale, molding soil, removal of layers paint, deburring, smoothing roughness, matting, hardening and polishing surfaces.

- Volume 990 liters;

- Productivity is from 6 to 10 sq.m / h;

- Air flow from 283 to 452 l / min;

- Air pressure from 4 to 8 bar.

The device allows to produce prototypes and functional products from various types of plastics. Thanks to a wide range of print settings, it is possible to adjust the production speed and detailing of the final product depending on the needs. The use of additive technology also makes it possible to create products with the complex geometry, including various internal structures, which are either impossible or costly to do with traditional production methods.

- Large print area 223 × 223 × 205 mm;

- Prints: PLA, ABS, Nylon;

- Layer thickness (mm): 0.2;

- Print speed: 30-300 mm / s;

- Platform: heated;

- Thread Diameter (mm): 2.85.

The device allows to produce prototypes and functional products from various types of plastics. Thanks to a wide range of print settings, it is possible to adjust the production speed and detailing of the final product depending on the needs. The use of additive technology also makes it possible to create products with the complex geometry, including various internal structures, which are either impossible or costly to do with traditional production methods.

- "Nozzle diameter 0.4 mm;

- Working material PEVA, ABS, PVA, HIPS, PLA;

- Minimum layer thickness 0.1 mm;

- Maximum layer thickness 0.4 mm;

- Construction speed 100 mm / s;

- Workspace width 200 mm;

- Depth of working space 200 mm;

- Height of working space 180 mm ".

The device allows to produce prototypes and functional products from various types of plastics. Thanks to a wide range of print settings, it is possible to adjust the production speed and detailing of the final product depending on the needs. The use of additive technology also makes it possible to create products with the complex geometry, including various internal structures, which are either impossible or costly to do with traditional production methods.

- PLA plastic type Size of construction area 252 × 199 × 150 mm;

- XY axis positioning accuracy 11 µm;

- Z axis positioning accuracy 2.5 µm;

- Nozzle diameter (mm) 0.4;

- Operating temperature of extruder 160 - 190C.

The station allows to solder microelectronic components.

- The range of operating temperatures of the soldering iron: 200- 480 ° C;

- Operating temperature range of the dryer: 100-480 ° С;

- Maximum air flow rate: 120 l / min.

The source allows to adjust and controll dc power. The user can controll the voltage and the maximum current value at the output from the source

- Output voltage, V 2 x 0 - 50 (0-30);

- Output current, A 2 x 0 - 2 (0-3);

- Pulsation level by current, mА≤ 3 by voltage, mV ≤ 0.5 (≤ 0.5);

- The effect of load,% current ≤ 0.2 ± 1 mA by voltage ≤0.01 ± 1 mV (≤0.01 ± 3mV);

- Display of output current and voltage;

- Two 3-digit LED matrix.

Provides real-time data recording, up to the full bandwidth value, the same memory length for all values of the time base, complex synchronization modes allowing to select the necessary signals and 16 types of standard automatic measurements in all models. The ability to perform a fast Fourier transform (FFT), as well as mathematical functions of addition, subtraction and multiplication of waveforms, allow you to analyze the operation of the circuits, determine their characteristics and solve problems

- Digital type Number of analog channels 2 Bandwidth, MHz 100;

- Sampling rate per channel 2 GHz;

- Memory capacity per channel 2500 points;

- Additional functions applied modules Tds2000c series;

- State Registered yes.

The three-axis CNC milling machine allows milling and mechanical engraving of the material. Using the methods of engraving it is possible to manufacture the base element of printed circuit boards by removing copper from the surface of foiled fiberglass. Additionally, it is possible to install the kinematics of the 4th axis, which expands the capabilities of the machine tool and allows production of products of complex shapes

- XY table size 170 mm x 110 mm;

- Max. working area 152.4 mm x 101.6 mm x 60.5 mm;

- Max. workpiece weight 0.5 kg.

The three-axis low power CNC milling machine allows milling and mechanical engraving of the material. It is capable to mill materials with a density up to 2000 kg / m3. Using the methods of engraving it is possible to manufacture the base element of printed circuit boards by removing copper from the surface of foiled fiberglass. Thanks to the closed chamber it can be operated in relatively clean rooms.

- Max. Working area mm 203.2 x 152.4 x 60.5;

- Max. workpiece weight 2 kg;

- Spindle speeds up to 7000 rpm.

The three-axis CNC milling machine allows milling and mechanical engraving of the material. It is capable to mill materials with a density up to 3000 kg / m3. Using the methods of engraving it is possible to manufacture the base element of printed circuit boards by removing copper from the surface of foiled fiberglass. Additionally, it is possible to install the kinematics of the 4th axis, which expands the capabilities of the machine tool and allows production of products of complex shapes

- Materials to be processed plastics, wood, non-ferrous metals Movement along the X / Y / Z axis, mm X x Y x Z: 500 x 400 x 155 mm;

- Distance from spindle nose to table max. 254 mm;

- The size of the table length x width: 550 x 420 mm;

- The maximum weight of the workpiece is 20 kg;

- XY motors servos, 60W 0.001 mm mechanical resolution;

- Positioning accuracy ± 0.1 mm / 300 mm, no load.

Designed for lead-free soldering. There is an automatic compensation for heat loss of the tip, it is possible to set the range of permissible temperatures, the time of disconnection from the network and the temperature reduction of the tool in case of its long idle time.

- Power supply: 230V, 50Hz, 80W;

- Temperature range: 204- 482C;

- Stability of temperature of idling: +/- 1,1C;

- Tip grounding resistance: no more than 2 ohms.

The machine has two modes of operation: cutting sheet materials and engraving (applying a monochrome image). Thanks to its power of 100 watts, it can cut a wide range of materials: paper, cardboard, various fabrics, acrylic, mdf, plywood, etc. It also allows laser engraving on the listed types of materials. It is not suitable for cutting metals. The machine allows you to make both functional products, and to be a member of the rapid prototyping cycle.

- Working area, mm 860 x 610, expandable to 960 x 610;

- Maximum dimensions of the workpiece when all the doors are closed 990 x 635 x 177mm;

- All doors are open 990 x ∞ x 177;

- Size of the desktop, mm 1025 x 705;

- Accuracy is 0.254 mm or 0.1% stroke.

Great for printing images on t-shirts, shorts, tablecloths, metal plates, etc.

- Power consumption: 1600 W;

- Timer: 0-999 s;

- Maximum temperature: 250 ℃;

- Working field: 40 x 50 cm.

Designed for molding plastic in silicone molds and composites. The process of working with silicone and composite forms are similar. Suitable for two-component plastics, resins and rubbers.

- The volume of the containers for polymer is 1000 cm3;

- Maximum size of the form 460x460x390 mm;

- Dimensions of VALM 743x675x1545 (ShhDhV) mm;

- Time to create a working vacuum (no more than) 4.8 minutes (no form);

- Vacuum discharge time 30 sec;

- Extreme residual pressure of the vacuum pump 1.1 mm Hg.